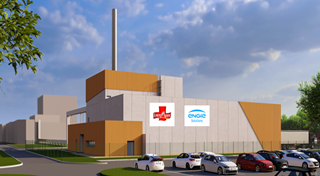

ENGIE Solutions & LIEBIG - Recovery of waste heat and cogeneration to optimize production costs

Description

In order to reduce the carbon footprint, while maintaining competitiveness, ENGIE Solutions connected to the SITA incineration plant, a subsidiary of SUEZ, nearby to recover the high temperature waste heat (35b) from the incineration process and to recycle it into superheated 25b steam to be distributed over 2 km to GB Foods for use at 10b via a 15 t/h regulator

“53,000 tons of steam supplied”

We have installed a 3 MWth C13 cogeneration engine to ensure both the production of hot water necessary for cleaning and part of the steam necessary for the proper functioning of the soup manufacturing process.

Finally, we maintained existing gas production to ensure 100% availability on steam.