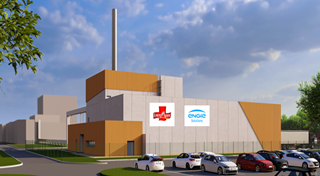

ENGIE Solutions is undertaking a decarbonization project with Lesaffre at its Marcq-en-Baroeul factory (59)

Description

Thanks to the installation of 2 high-power heat pumps by ENGIE Solutions, the heat created by Lesaffre's fermentation activity will be reused. This new waste heat recovery unit will be commissioned in 2025 at the heart of the Group's largest yeast factory in the world on its historic site in Marcq-en-Baroeul.

Thus, Lesaffre, a leading global player in the field of fermentation for 170 years, will be able to cover 70% of its heat needs and avoid the emission of around 30,000 tonnes of CO₂ per year and reduce its water consumption by 150,000 m³ per year.

As part of a 15-year partnership, Lesaffre contacted ENGIE Solutions to recover the energy effluents linked to its production process and thus reduce its dependence on fossil fuels. This project is part of the process undertaken by Lesaffre for several years to control its carbon footprint and energy consumption.

Concretely, our solutions:

* Mesh the yeast production workshop (exothermic process) and the drying workshop of these same yeasts (heating of the drying air by the heat pumps)

* Recover energy effluents linked to its production process to reduce dependence on fossil fuels

* Install two high-power heat pumps (19 MWth) to transform the heat produced in the fermentation workshop

* Capture the heat generated on site and currently dissipated into the air by air-cooling towers, to redirect it to another production stage requiring the use of heat, currently generated by a gas boiler room

* Allow Lesaffre to decarbonize two thirds of its activity on the site

* Support the site in its development projects